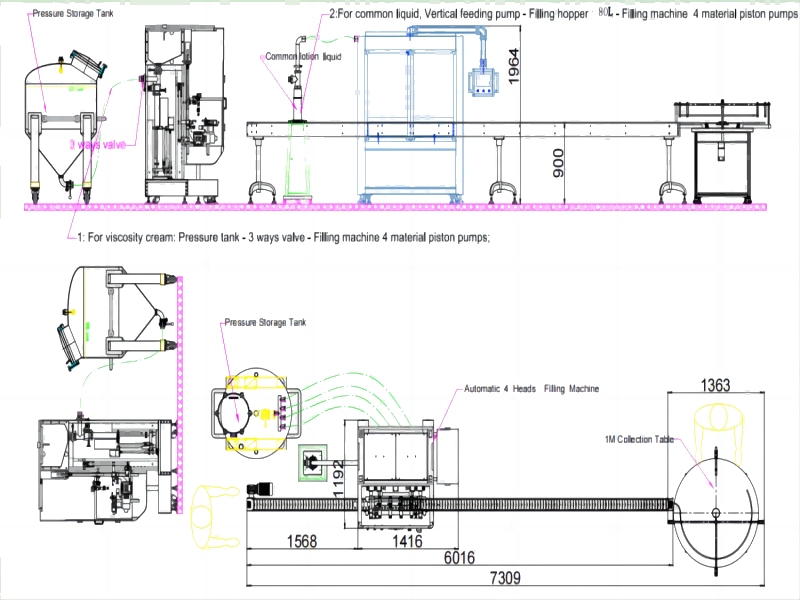

In the fast-paced and ever-evolving cosmetics industry, efficiency and precision are crucial. In response to the needs of the industry, Sina Ekato launched an automatic filling line for cosmetics production equipment. This advanced technology not only ensures the smooth progress of the production process, but also ensures the quality and accuracy of each product.

The core of this automatic filling line is the TVF-4 automatic filling machine. This complex mechanical design is used to fill cosmetic liquid products with the highest precision. Its intelligent control and high-speed operation make it an excellent choice for manufacturers seeking to optimize their production processes.

In order to meet the individual needs of customers, the filling line can be customized according to specific requirements. One of the customization options is a pressure tank. The tank can be customized to suit different product quantities, ensuring a continuous and uninterrupted production process.

In order to meet the individual needs of customers, the filling line can be customized according to specific requirements. One of the customization options is a pressure tank. The tank can be customized to suit different product quantities, ensuring a continuous and uninterrupted production process.

Another important component of the automatic filling line is the automatic feeding machine. The machine effectively transfers cosmetics from the storage area to the filling machine, eliminating manual labor and further increasing productivity.

Another important component of the automatic filling line is the automatic feeding machine. The machine effectively transfers cosmetics from the storage area to the filling machine, eliminating manual labor and further increasing productivity.

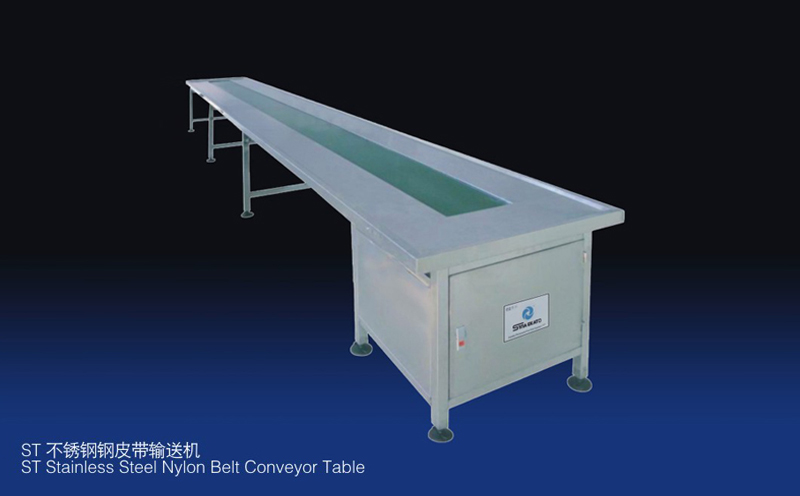

Considering efficiency and hygiene, automatic stainless steel conveyors play a vital role in the production line. The conveyor is easily adjustable and can be customized to the specific needs of each customer. Its seamless construction and easy-to-clean design ensure that the highest hygiene standards are met.

Considering efficiency and hygiene, automatic stainless steel conveyors play a vital role in the production line. The conveyor is easily adjustable and can be customized to the specific needs of each customer. Its seamless construction and easy-to-clean design ensure that the highest hygiene standards are met.

Conveyors

Finally, the automatic filling production line is completed by the bottle sorting machine. As an important part of the packaging of cosmetics, the machine can easily carry out the control inspection of the product and facilitate subsequent packaging and distribution.

In short, Sina Ekato’s automatic filling line for filling cosmetic liquid products is a game changer for the cosmetics industry. Its advanced equipment, such as TVF-4 automatic full liquid filling machine, pressure storage tank, automatic loading machine, automatic stainless steel conveyor, collection table, etc., ensure smooth and efficient operation. The automatic filling line can be customized according to the individual needs of customers, which greatly changes the production process and ensures the precision and high quality of cosmetics. Stay ahead of the competition by filling cosmetic liquids with Sina Ekato’s automatic filling line.