Since the 1990s, Sina Ekato has established itself as a reputable manufacturer of cosmetic machinery, catering to the diverse needs of customers worldwide. With a wide product range that includes the Customed SME-B-7000L vacuum homogenizer emulsifier, PME-4000L preheat dispersion pan, and CG-6000L storage tank, Sina Ekato continues to be a leader in the industry.

- SME-B-7000L Vacuum Homogenizer emulsifying Mixer

- CG-6000L Storage Tank

In the bustling production workshop of Sina Ekato, the Customed SME-B-7000L vacuum homogenizer emulsifier, PME-4000L preheat dispersion pan, and CG-6000L storage tank are in high demand. These top-of-the-line machines are crucial in the production of countless cosmetic products, ensuring high-quality and consistent results.

- SME-B-7000L in production

- SME-B-7000L in production

The Customed SME-B-7000L vacuum homogenizer emulsifier is a versatile machine that combines the functions of emulsification, homogenization, and vacuum degassing. This powerful equipment effectively breaks down particles and blends ingredients, resulting in smooth and stable cosmetic formulations. Its large capacity of 7000 liters allows for efficient and bulk production, making it an ideal choice for cosmetic manufacturers.

- PME-4000L in production

- PME-4000L in production

The PME-4000L preheat dispersion pan, another essential machine at Sina Ekato’s production workshop, plays a crucial role in preheating and dispersing various ingredients. This pan ensures that the ingredients are adequately heated and mixed before being transferred to the vacuum homogenizer emulsifier. With a production capacity of 4000 liters, this dispersion pan can handle a significant volume of raw materials, ensuring a seamless production process.

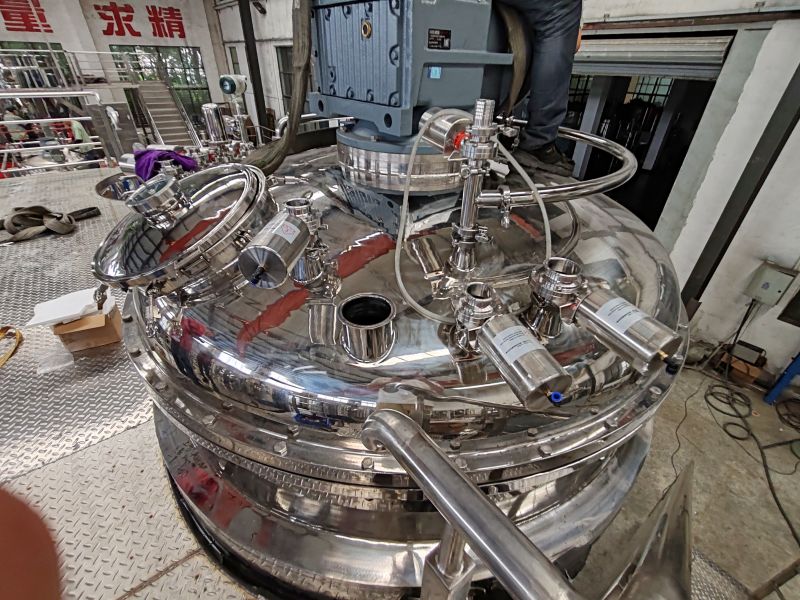

- CG-6000L Storage tank

- CG-6000L Storage tank

Completing the production line is the CG-6000L storage tank. This tank provides ample storage space for both raw materials and finished products. Its 6000-liter capacity allows for efficient inventory management, reducing the risk of production interruptions due to shortages. The storage tank is designed to maintain the quality and integrity of the cosmetic products, ensuring that they are ready for packaging and distribution.

At Sina Ekato, the production workshop operates at full capacity, with these three machines working seamlessly together to meet the high demands of the cosmetic industry. The skillful technicians and engineers employed by Sina Ekato ensure that these machines are always in optimal condition, maximizing productivity and minimizing downtime.

Sina Ekato’s commitment to quality extends beyond its machinery. The company continually invests in research and development to stay at the forefront of technological advancements in the cosmetic industry. This dedication to innovation allows Sina Ekato to provide its customers with cutting-edge solutions that enhance their manufacturing capabilities.

With a global presence, Sina Ekato has built a strong reputation for its reliable and high-performing cosmetic machinery. A diverse customer base trusts Sina Ekato to deliver consistent and superior quality products, meeting their specific production needs.

In conclusion, Sina Ekato’s production workshop is a hive of activity, with the Customed SME-B-7000L vacuum homogenizer emulsifier, PME-4000L preheat dispersion pan, and CG-6000L storage tank playing vital roles in meeting the demands of the cosmetic industry. Through its commitment to innovation and customer satisfaction, Sina Ekato continues to be a leading manufacturer of cosmetic machinery, providing reliable and efficient solutions for cosmetic manufacturers worldwide.