In the ever-changing cosmetics manufacturing industry, the demand for high-quality equipment is paramount. As a leading brand in the industry, Sina Ekato is committed to meeting this need, providing customized products for Vietnamese clients. Sina Ekato emphasizes innovation and efficiency, offering a range of machinery designed to enhance cosmetics production efficiency, ensuring businesses can keep pace with market trends and consumer demands.

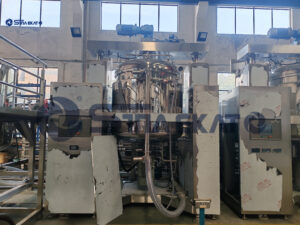

One of Sina Ekato’s standout products is its series of hydraulic lifting vacuum emulsifying mixers. These machines are essential equipment for producing creams, lotions, and other cosmetics, providing a seamless mixing process that ensures uniform product texture and consistency. The series includes various models to meet the production needs of businesses ranging from small to large.

The **SME-100L Hydraulic Lifting Vacuum Emulsifying Mixer** is ideal for small businesses or startups, enabling them to produce high-quality cosmetics without significant investment. This model combines high efficiency with ease of use, helping manufacturers prepare emulsions quickly and effectively.

For users with higher production demands, the **SME-200L and SME-500L hydraulic lifting vacuum emulsifying mixers** offer increased capacity while maintaining the same high-quality standards. Designed for handling larger volumes, these mixers are ideal for growing businesses requiring reliable and efficient equipment to meet increasing demand.

Sina Ekato also provides large manufacturers with the **SME-AE500L and SME-2000L hydraulic lifting vacuum emulsifying mixers**. These advanced models incorporate numerous features that enhance emulsification processes, such as more precise temperature control and vacuum performance, ensuring that the final product meets the highest quality standards.

For the most demanding production environments, the **PME-5000L and PME-H5000L Heated Vacuum Emulsifying Mixers** are ideal. Designed for high-volume production, these machines can handle large quantities of material while providing precise control over the emulsification process. The heating function enables the mixing of heat-sensitive components, ensuring the product remains intact throughout the mixing process.

Sina Ekato is committed to providing products that meet the specific needs of Vietnamese customers, a commitment exemplified in its customized solutions. They offer a range of emulsifying mixers to meet varying production scales and requirements, helping local manufacturers produce high-quality cosmetics that are competitive in both domestic and international markets.

The logistics and transportation of these goods were equally impressive. Sina Ekato ensured efficient product transport, with four fully loaded 40-foot open containers ready to deliver their state-of-the-art equipment to customers throughout Vietnam. This commitment to timely delivery meant that businesses could quickly set up production lines and begin production, avoiding unnecessary delays.

In summary, Sina Ekato distinguishes itself as an industry leader in cosmetic machinery, providing customized solutions to meet the unique needs of Vietnamese customers. With its series of hydraulic lifting vacuum emulsifying mixers, businesses can enhance production capacity and deliver high-quality cosmetics to the market. The combination of innovative technology, efficient logistics, and a customer-centric approach makes Sina Ekato a trusted partner for Vietnamese manufacturers.