The cosmetic industry is constantly evolving and new products and technologies are constantly being introduced. One of the most important aspects of cosmetic production is the efficient and effective mixing of ingredients. This is where the high shear movable lifting homogenizer plays a key role.

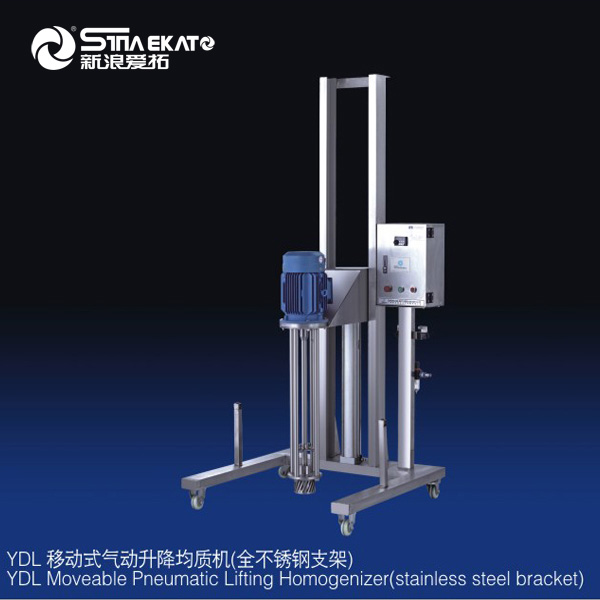

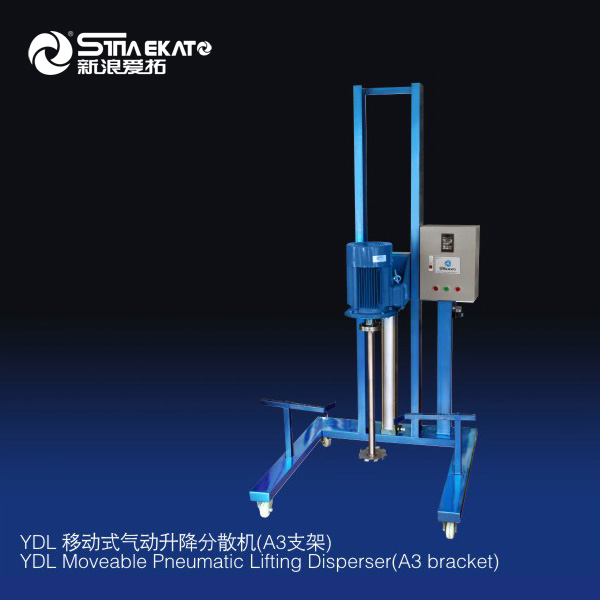

YDL movable pneumatic lifting homogenizer is one kind of mixer that is popular in the industry. This innovative device, manufactured by SinaEkato, has revolutionized the way cosmetics are made. It is designed to provide high speed, uniform mixing resulting in a consistent and high quality product.

Compared with traditional mixers, YDL movable pneumatic lifting homogenizer has many advantages. First, its removable design allows for easy movement and positioning. This means it can be transported effortlessly to different areas of the production facility, reducing the need for multiple mixers. This not only saves space, but also simplifies the production process.

In addition, the homogenizer’s pneumatic lifting mechanism ensures smooth, precise movement. This is especially important when working with delicate ingredients that require gentle mixing. The homogenizer’s adjustable lifting speed further enhances its versatility, allowing customization to specific product requirements

In addition, the homogenizer’s pneumatic lifting mechanism ensures smooth, precise movement. This is especially important when working with delicate ingredients that require gentle mixing. The homogenizer’s adjustable lifting speed further enhances its versatility, allowing customization to specific product requirements

One of the main features of YDL Movable Pneumatic Lifting Homogenizer is its high shear capacity. This means it effectively breaks down particles, ensuring thorough mixing and emulsification of ingredients. This is critical for the cosmetics industry, where the consistency and smoothness of the final product is paramount.

In addition, YDL movable pneumatic lifting homogenizer is equipped with advanced safety features. This includes emergency stop buttons and overload protection, ensuring the health of the operator and preventing any accidents or equipment damage.

In conclusion, SinaEkato’s YDL Movable Pneumatic Lifting Homogenizer revolutionized the cosmetics industry by providing an efficient and effective solution for mixing ingredients. Its mobile design, high shear capacity and advanced safety features make it a valuable asset to any cosmetics production facility. With the growing demand for high-quality cosmetics, investing in such innovative equipment is crucial for businesses that want to stay ahead in a highly competitive market.

In conclusion, SinaEkato’s YDL Movable Pneumatic Lifting Homogenizer revolutionized the cosmetics industry by providing an efficient and effective solution for mixing ingredients. Its mobile design, high shear capacity and advanced safety features make it a valuable asset to any cosmetics production facility. With the growing demand for high-quality cosmetics, investing in such innovative equipment is crucial for businesses that want to stay ahead in a highly competitive market.