Description

Application

Products are widely used in food, beverage, pharmaceutical, bioengineering, water treatment, daily chemical, petroleum and chemical industries.

In strict accordance with DIN, SMS, 3A, IDF, ISO and other domestic and foreign standards design.

All the technologies have reached the leading level of the same industry, in line with GMP, QS, HACCP requirements

Performances And Features

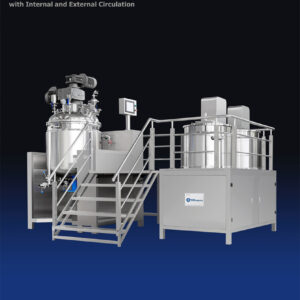

The pot body is a three-layer stainless steel structure, and the outermost layer is a thermal insulation layer. The intermediate layer is a heating layer that heats the medium through an electric heating generator to heat the material. The inner layer is the direct contact layer with the material, and the parts of the contact material are made of stainless steel SS316L. The whole equipment complies with GMP standard.

The whole equipment complies with GMP standard. All contact materials are made of imported stainless steel. The interior surface of the vessel is subjected to mirror polishing 300EMSH(sanitary level), which is in accordance with sanitary requirements

The stirring pot body and the stirring pot cover are connected with flange sealing,

The stirring tank and the stirring tank cover can feed, discharge, observe, measure temperature, measure pressure, steam fractionation, safety vent and other process pipe holes according to the process requirements.

360°cleaning ball – CIP Cleaning 360 water sprinkler inside the pot. Inlet water tube shall be connected

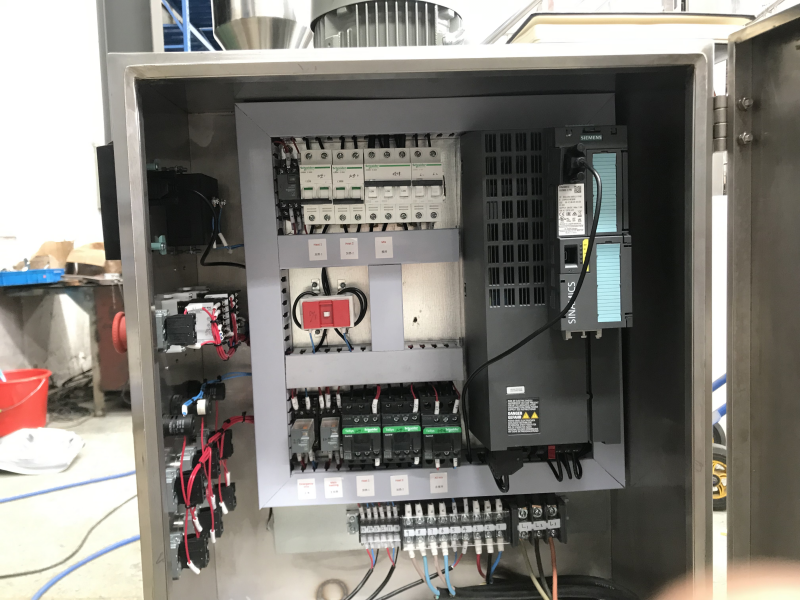

The dispersion system is driven by Siemens motors, which transmit power through a drive shaft (which is mechanically sealed) and a coupling to a dual dispersion disc in the work unit. Speed regulation can be achieved by controlling the Siemens inverter in the electrical box

To ensure the control of the whole machine is more stable, the electric appliancesadopt imported configurations, so as to fully meet the international standards

Technical Parameter

| Product name | Stirring pot volume(L) | Motor power(KW) | Mixing Speed(e/min) | Heating power | pot pressure(Mpa) |

| SME-B-50L | 50L | 5.5(KW) | 0-3400(r/min) | 3KW | 0.1-0.15(Mpa) |

Product Details

Note: The picture is customized for reference only

Product Details

- SME-B-50L-Mobile-Mixing-pan

- SME-B-50L-Mobile-Mixing-pan

- 3L-Funnel-hopper

- 3L-Funnel-hopper

Pot-cover

- Siemens-Motors

- Manhole-with-sight-glass

Pot-Body

- Heating-elements

- Temperature-control

- Discharge-valve

- Flange-lock-connection-with-buckle

- Control-box-electric-control-operation-button

- Electric control button

- Siemens frequency converter

Control-the-inside-of-the-electrical-box

Relevant Machines

We can offer machines for you as following

Reverse osmosis water purifier, vacuum homogenizing emulsifier. aseptic storage tank, drying sterilizer, ointment filling machine. conveying workbench, code printer, labeling machine, aluminum foil sealing machine, shrink film machine

Click the picture to jump to the link related to the product

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Stainless steel storage tank

- Cream & Paste Filling Machine

- Splint type sachet packing machine

- Tube Filling And Sealing Machine

- Automatic aluminum foil sealing machine

- Labelling Machine

- Automatic Capling Machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

- Packing

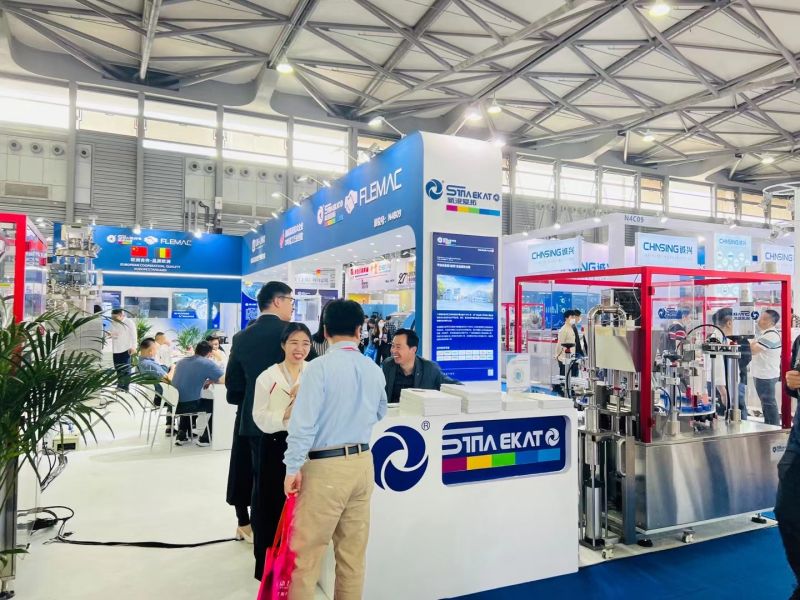

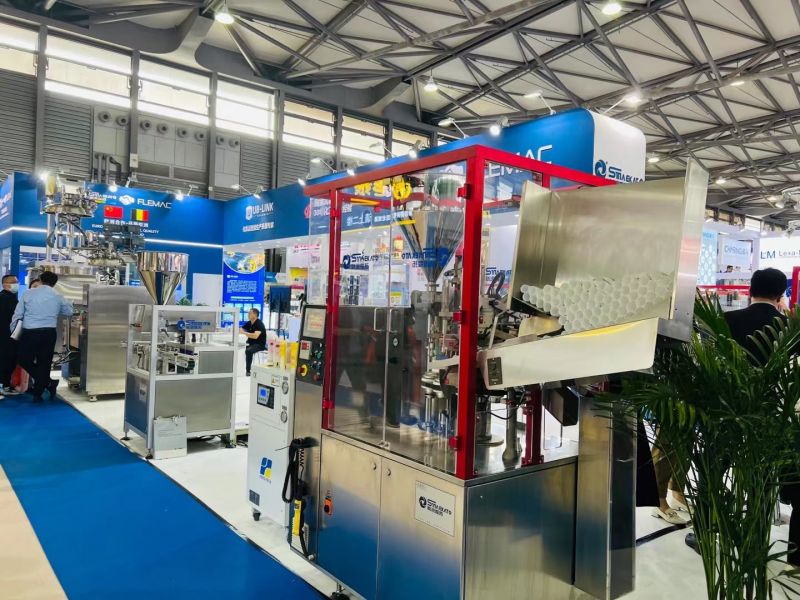

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

.jpg)

Reviews

There are no reviews yet.