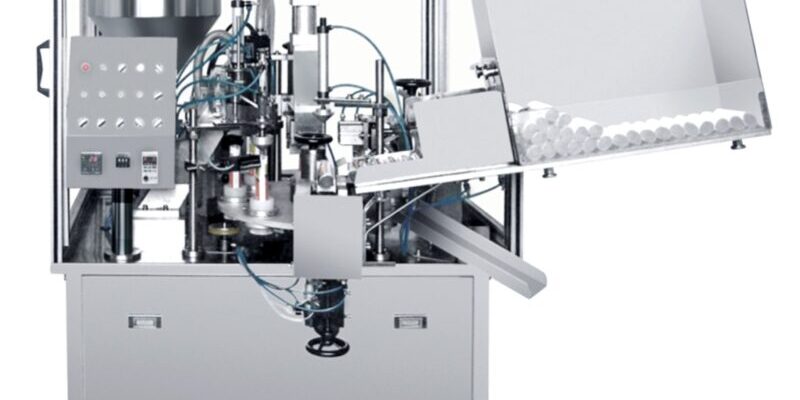

The cosmetics industry is known for continuous innovation and technological advancement. As the global demand for cosmetics continues to grow, manufacturers are always looking for efficient and reliable equipment to streamline their production processes. Sina Ekato, a well-known leader in the industry, recently launched an automatic laminate tube filling and sealing machine that has dramatically changed the way cosmetics are packaged and delivered.

Sina Ekato GZF automatic laminated tube filling and sealing machine is a combination of foreign technology and GMP optimization design of cutting-edge high-tech equipment. This innovative machine provides the perfect solution to meet the stringent requirements of the cosmetics industry. Its remarkable features are reasonable structure, complete functions, convenient operation, accurate loading, stable operation and low noise.

Main features and advantages:

1. Advanced technology: The GZF automatic laminated tube filling and sealing machine adopts the most advanced technology design to ensure the accurate and efficient filling of liquid to high-viscosity fluid materials (paste). The introduction of foreign technology ensures industry-leading performance.

2. GMP optimization: The optimized design of the equipment follows GMP standards to provide cosmetics manufacturers with strict quality control guidelines. This optimization ensures that equipment meets the highest industry standards for hygiene, safety and product efficacy.

3. Easy operation: The machine is equipped with programmable logic controller (PLC), making the whole filling and sealing process easy to operate and control. The user-friendly interface simplifies machine programming and tuning, saving time and reducing the possibility of errors.

4. Accurate and consistent output: The automatic stack filling and sealing machine ensures accurate and consistent filling, eliminates product waste and maximizes efficiency. This accuracy ensures that each tube is filled with the exact amount of product, maintaining brand consistency and customer satisfaction.

5. Batch number code: The machine has a folding function, which can directly print the batch number code including the production date to the tube. This automation greatly reduces the risk of human error and enhances traceability throughout the supply chain.

In the highly competitive cosmetics industry, Sina Ekato automatic laminate tube filling and sealing machine has changed the way cosmetics are produced and packaged. With its advanced technology, GMP optimized design and user-friendly operation, this high-tech equipment sets new standards for efficiency, accuracy and productivity. By investing in such innovative machines, cosmetic manufacturers can improve the production process, reduce costs, and stay ahead of the competition.